Structural mechanics is the study of the mechanical behavior of solids and structures. Aerospace structures differ from other structures due to the highest demands for performance and lightweight. Modern aerospace structures typically require the use of composite materials, advanced multifunctional materials and thin-walled constructions. To obtain the level of performance required from flight structures, thorough knowledge of material limitations, structural stability and strength considerations are needed. Current research in the Department emphasizes the characterization of advanced materials, material and structural stability, computational material/structural design, thermo-mechanical and electro-mechanical interactions, structural dynamics, multiscale modeling, multifunctional structures, morphing structures, aeroelasticity, structural health management and design optimization. This specialization covers theory, computations, experiments and implementation issues, as well as the study of specific cutting edge aerospace vehicles.

Structural mechanics is the study of the mechanical behavior of solids and structures. Aerospace structures differ from other structures due to the highest demands for performance and lightweight. Modern aerospace structures typically require the use of composite materials, advanced multifunctional materials and thin-walled constructions. To obtain the level of performance required from flight structures, thorough knowledge of material limitations, structural stability and strength considerations are needed. Current research in the Department emphasizes the characterization of advanced materials, material and structural stability, computational material/structural design, thermo-mechanical and electro-mechanical interactions, structural dynamics, multiscale modeling, multifunctional structures, morphing structures, aeroelasticity, structural health management and design optimization. This specialization covers theory, computations, experiments and implementation issues, as well as the study of specific cutting edge aerospace vehicles.

Soft Materials Research Lab

Selected Research Projects of the Seven Faculty Members of the Structural Mechanics Group:

Professor

Professor

Research interests: Multifunction active aeroelastic structural modeling, analysis and design; structural health management

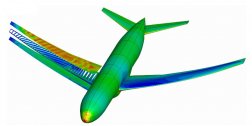

Coupled Nonlinear Flight Dynamics/Aeroelasticity of Very Flexible Aircraft

The mission profile of high-altitude long-endurance (HALE) UAV's requires new structural design paradigms to achieve effective weight and corresponding vehicle performance. By taking advantage of the flexibility of lifting surfaces instead of fighting it, our research has been uncovering fundamental nonlinear mechanisms that couple aeroservoelasticity and flight dynamics.

The mission profile of high-altitude long-endurance (HALE) UAV's requires new structural design paradigms to achieve effective weight and corresponding vehicle performance. By taking advantage of the flexibility of lifting surfaces instead of fighting it, our research has been uncovering fundamental nonlinear mechanisms that couple aeroservoelasticity and flight dynamics.

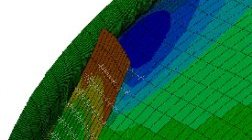

Aerothermoelastic Modeling of Hypersonic Vehicles for Control Design

Air-breathing hypersonic vehicles (HSV) present strong interactions among aerodynamics, elastic airframe and control effector deformations, heat transfer and propulsion system (itself tightly integrated into the lifting body). As part of a collaborative center with the AFRL and in collaboration with NASA, our research focuses in two main areas: (i) development and validation of simple (low-order) control models that can characterize the main aerothermoelastic effects coupled with propulsion in a 6 DOF flight dynamics simulation of HSV; and (ii) determination on how to appropriately modify vehicle configuration to improve its dynamics controllability without compromising vehicle performance.