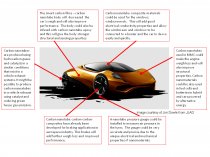

The fascinating mechanical and electrical properties of carbon nanotubes can be exploited in many applications, which might include lightweight and strong vehicle or aircraft body with in situ health monitoring and self healing properties, superior aircraft or car brake carbon-carbon composite discs that could dissipate a heat more efficiently, strong and interactive windscreens with de-icing properties.

The fascinating mechanical and electrical properties of carbon nanotubes can be exploited in many applications, which might include lightweight and strong vehicle or aircraft body with in situ health monitoring and self healing properties, superior aircraft or car brake carbon-carbon composite discs that could dissipate a heat more efficiently, strong and interactive windscreens with de-icing properties.

Even a few percent loading of carbon nanotubes in polymer matrix could make non conductive polymers to conduct electricity and solve many problems with static electricity that could be a spark of fire within a vehicle.

In an aircraft wing carbon nanotubes conductivity could provide de-icing and lighting strike protection with reduction of weight. They could improve strength of a body in an aircraft or a vehicle, decrease weight and make army vehicle or military aeroplane electromagneticly invisible. Carbon nanotubes and nanofibres could be added to metals in order to improve properties and make lighter engines, they could be used in tyres ispead of carbon black to improve wear properties and provide in sity pressure sensing.

However, there are a number of problems to overcome in a development precess of carbon nanomaterials application. The properties of nanotubes need to be optimised for a specific application. Nanotubes must be efficiently dispersed and bonded to the material they are reinforcing (the matrix), in order to maximize load transfer. Many companies managed to solve some of these problems with more or less success and developing new composite materials from various polymers and carbon nanotubes with improved mechanical, thermal or electrical properties. There are still many opportunities for improvement of properties of traditional engineering materials and their replacement with use of carbon nanomaterials in transport and in many other applications.