Printed Electronics Sector Takes Hard Look at the Flexible Future

By Paula Doe, SEMI Emerging Markets

The flexible and printed electronics community reports encouraging progress in the materials and process ecosystem needed for commercial production — and an increasingly realistic focus on applications that best capitalize on the technology’s strengths. Best near-term prospects now look to be sturdy light-weight displays, smart sensor systems, and flexible and large area biomedical sensors and imagers.

Improving technology for everything from barrier films to roll-to-roll in-line testing may mean printed or flexible electronics will start to see some more significant commercial applications in the next few years. Judging from the reported status of sturdy lightweight displays, smart-enough sensor tags, and medical sensors and imagers at FlexTech Alliance’s annual conference last week in Phoenix, suppliers are increasingly targeting higher-value applications that can’t easily be made in other ways.

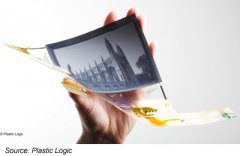

Light-weight, Rugged Displays

“This industry is starting to become reality, ” asserted Plastic Logic CEO Indro Mukerjee, “We’ve moved from a science project to an industrial process, and have created a value chain with partners to make the business possible.” He has moved the flexible display company away from marketing its own e-reader to supplying its electrophoretic display on flexible backplane module to a wide range of new users, now working with partners making outdoor signs, watches, automobiles, smart cards, and industrial indicators. He’s also promoting the company’s flexible TFT backplane for use in other markets, and aggressively pursuing LCD makers to transfer the production process for scaling. “The technology frontier business is not for the faint hearted, ” he noted. “We’re going for it at Plastic Logic.”