Printing sensing devices is not a novelty. For instance, many vaccines shipped across the world now have a printed temperature label which alerts medical staff if the cold chain has been broken during transport and storage. However, these labels are not electronic devices: the ink undergoes a chemical reaction and changes colour when the temperature is too high.

Printing sensing devices is not a novelty. For instance, many vaccines shipped across the world now have a printed temperature label which alerts medical staff if the cold chain has been broken during transport and storage. However, these labels are not electronic devices: the ink undergoes a chemical reaction and changes colour when the temperature is too high.

Electronic sensors are usually more complex and manufacturing can therefore be more challenging. There are multiple layers of materials and the devices require metal interconnects. The manufacturing technique is selected based on the material properties, cost, and the resolution. For many years, printing (and in particular screen-printing) has been used to make sensors based on specialized ceramic materials. The problem is that these sensors require a sintering process which makes them incompatible with plastic components, due to melting and deformation.

In contrast, the new sensors are based on inks that can be printed directly on plastic substrates. They offer advantages such as flexibility, thinness, light weight and, in some cases, the potential to be manufactured with roll-to-roll equipment. What it means is that these sensors will be able to go where no sensor has gone before. For example, think of curved surfaces, ultra-thin devices or shock-resistant devices.

While there are many flexible sensors still in early R&D phase, IDTechEx has identified the technologies that are emerging and now near commercialization. Those are:

• Printed gas sensors on plastic

• Printed temperature sensors

• Flexible photodetectors

• Flexible piezoelectric sensors

• Flexible digital X-ray sensors

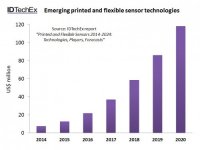

2014 will be the year when some of these sensors will start shipping to end users. By 2020, the combined market value of the sensor modules will be worth almost $120 million.

Fig. Market forecast (at sensor module level) for emerging printed & flexible sensor technologies

Best Buy sucks- how to save on electronics

by Best_Info_EVERI hate Best Buy. They are inherently more expensive than a lot of other retailers. They have terrible return policies, had the poorest rating for customer service last year, and the management consists of a bunch of douchebags. If you have ever visited the site bhphotovideo(.)com, then you realize how overpriced retail stores are for electronics. The great thing, is that stores like HHGregg will haggle price with you because they get commission on sales, just like a car dealership. Do your research on the web, get the price and information printed out and walk in there. They will try to say something like, "Well a lot of those interent companies are fly-by-night and aren't reliable or even exist

How to Haggle Electronics Below Retail

by FU_BestBuyI hate Best Buy. They are inherently more expensive than a lot of other retailers. They have terrible return policies, had the poorest rating for customer service last year, and the management consists of a bunch of douchebags. If you have ever visited the site bhphotovideo(.)com, then you realize how overpriced retail stores are for electronics. The great thing, is that stores like HHGregg will haggle price with you because they get commission on sales, just like a car dealership. Do your research on the web, get the price and information printed out and walk in there. They will try to say something like, "Well a lot of those interent companies are fly-by-night and aren't reliable or even exist

PCB guitar electronics....

by aintdisclosinI have a 70's Les Paul Custom copy. It's actually a pretty decent one from what I read on the interwebs. Anyway, I bought some upgraded pickups, and opened the control cavity for the first time to find the pots mounted on a fucking printed circuit board, like Gibson is doing now. Ok, fine. So I desolder the old PUPS and solder up the new ones. And the shit don't work. A little research found me that those PCB's have really fragile traces on them and they seem to hold up to the initial solder-on at the factory but the heat of a desolder and resolder just kills them. The pots were probably fine, and I could have completely freed them from the board and used them in a 'normal' configuration, but I wanted a new switch anyway so I got a complete wiring kit on Ebay for $16, and did the deed...

Brand Protection Technology Manager — Optics.org

Through an ongoing commitment to developing innovative products that provide value to our customers, Sun Chemical is investing in facilities and technologies targeted at the evolving printed electronics market.

|

Hammond 1591ATCL Translucent Polycarbonate Project Box -- Inches (3.9" x 2" x 0.8") mm (100mm x 50mm x 21mm)

BISS (Hammond Manufacturing)

- Translucent Polycarbonate Multipurpose Plastic Enclosures

- Integral card guides accept 1.5 mm (0.062 ) P.C. cards.

- Designed to meet IP54. Flame Redardant

- Perfect for applications where parts, sensors or indicators need to be visible.

- Ideally suited for mounting printed circuit boards.

|

|

Samsung Assembly Printed Circuit Board Main Squall Part # Dc92-00382A

CE (Samsung)

- Samsung ASSY PCB MAIN;SQUALL DRY DC92-00382A

- This is a Genuine Factory OEM Replacement Part

- 90 Day Manufacturer Replacement Warranty Included

|

Printing sensing devices is not a novelty. For instance, many vaccines shipped across the world now have a printed temperature label which alerts medical staff if the cold chain has been broken during transport and storage. However, these labels are not electronic devices: the ink undergoes a chemical reaction and changes colour when the temperature is too high.

Printing sensing devices is not a novelty. For instance, many vaccines shipped across the world now have a printed temperature label which alerts medical staff if the cold chain has been broken during transport and storage. However, these labels are not electronic devices: the ink undergoes a chemical reaction and changes colour when the temperature is too high.