2. Carbon nanotubes (CNTs)

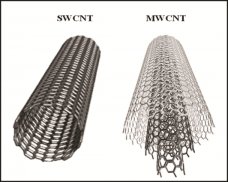

CNTs are long cylinders of covalently bonded carbon atoms which possess extraordinary electronic and mechanical properties. There are two basic types of CNTs: single-wall carbon nanotubes (SWCNTs) which are the fundamental cylindrical structure and multi-wall carbon nanotubes (MWCNTs) which are made of coaxial cylinders (, having interlayer spacing close to that of the interlayer distance in graphite (0.34 nm). These cylindrical structures are only few nanometre in diameter, but the cylinder can be tens of microns long, with most end capped with half of a fullerene molecule. It was first discovered by M. Endo in 1978, as part of his Ph.D. work at the University of Orleans in France, but real interest in CNTs started when ) first reported it in 1991. The field thrives after that and the first polymer composites using CNT as filler was reported by ).

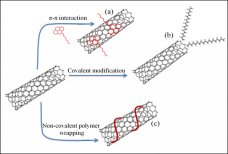

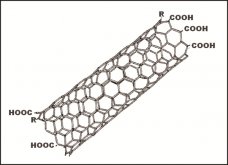

Figure 1.

Schematic diagrams of single-wall carbon nanotube (SWCNT) and multi-wall carbon nanotube (MWCNT)

Schematic diagrams of single-wall carbon nanotube (SWCNT) and multi-wall carbon nanotube (MWCNT)

2.1. Synthesis of carbon nanotubes

CNTs can be prepared using three methods which includes arc discharge, laser ablation and chemical vapor deposition (CVD). Most of these processes take place in vacuum or with process gases. CVD growth of CNTs can occur in vacuum or at atmospheric pressure. High quality and large quantities of nanotubes can be synthesized by these methods.

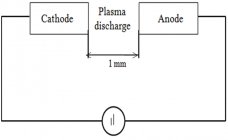

The carbon arc discharge method, initially used for producing C60 fullerenes, is the most common and perhaps easiest way to produce CNTs. ique produces graphitic impurities such as carbon soot containing amorphous carbon, anions and fullerens. In this method an inert gas atmosphere is created in the reaction vessel by passing an inert gas at controlled pressure. Two graphitic rods constitute the electrodes, between which a potential difference is applied. As the rods are brought closer, a discharge occurs, resulting in formation of plasma (.

ique produces graphitic impurities such as carbon soot containing amorphous carbon, anions and fullerens. In this method an inert gas atmosphere is created in the reaction vessel by passing an inert gas at controlled pressure. Two graphitic rods constitute the electrodes, between which a potential difference is applied. As the rods are brought closer, a discharge occurs, resulting in formation of plasma (. ectrode (cathode) while the smaller positive electrode (anode) is consumed. When a metal catalyst is used along with graphite, a hole is drilled in the carbon anode and it is filled with a mixture of metal and graphite powder. In this case, most nanotubes are found in soot deposited on the arc chamber wall.

ectrode (cathode) while the smaller positive electrode (anode) is consumed. When a metal catalyst is used along with graphite, a hole is drilled in the carbon anode and it is filled with a mixture of metal and graphite powder. In this case, most nanotubes are found in soot deposited on the arc chamber wall.

Figure 2.

Plasma arc discharge setup

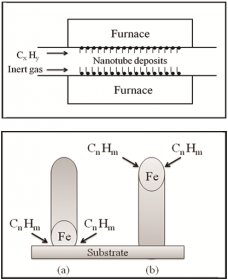

Laser ablation uses an intense laser pulse to vaporize a carbon target, which also contains small amount of metals such as nickel and cobalt and is placed in a tube furnace at 1200º C. As the target is ablated, inert gas is passed through the chamber carrying the grown nanotubes on a cold finger for collection (. This method mainly produces SWCNT in the form of ropes.