Graphene is Only as Strong as its Weakest Link: Experiments Determine Real-world Limits of Two-dimensional Carbon

There is no disputing graphene is strong. But new research by Rice University and the Georgia Institute of Technology should prompt manufacturers to look a little deeper as they consider the miracle material for applications.

The atom-thin sheet of carbon is touted not just for its electrical properties but also for its physical strength and flexibility. The bonds between carbon atoms are well known as the strongest in nature, so a perfect sheet of graphene should withstand just about anything. Reinforcing composite materials is among the material’s potential applications.

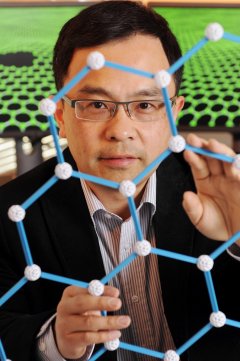

But materials scientists know perfection is hard to achieve. Researchers Jun Lou at Rice University and Ting Zhu at Georgia Tech have measured the fracture toughness of imperfect graphene for the first time and found it to be somewhat brittle. While it’s still very useful, graphene is really only as strong as its weakest link, which they determined to be “substantially lower” than the intrinsic strength of graphene.

“Graphene has exceptional physical properties, but to use it in real applications, we have to understand the useful strength of large-area graphene, which is controlled by the fracture toughness, ” said Zhu, who is an associate professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech.

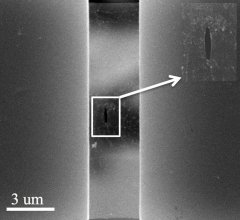

The researchers reported in the journal Nature Communications the results of tests in which they physically pulled graphene apart to see how much force it would take. Specifically, they wanted to see if graphene follows the century-old Griffith theory that quantifies the useful strength of brittle materials.

The researchers reported in the journal Nature Communications the results of tests in which they physically pulled graphene apart to see how much force it would take. Specifically, they wanted to see if graphene follows the century-old Griffith theory that quantifies the useful strength of brittle materials.

It does, said Lou, who is an associate professor of materials science and nanoengineering and of chemistry at Rice. “Remarkably, in this case, thermodynamic energy still rules, ” he said.

Imperfections in graphene drastically lessen its strength – with an upper limit of about 100 gigapascals (GPa) for perfect graphene previously measured by nanoindentation – according to physical testing at Rice and molecular dynamics simulations at Georgia Tech. That’s important for engineers to understand as they think about using graphene for flexible electronics, composite material and other applications in which stresses on microscopic flaws could lead to failure.

The Griffith criterion developed by a British engineer during World War I describes the relationship between the size of a crack in a material and the force required to make that crack grow. Ultimately, A.A. Griffith hoped to understand why brittle materials fail.

Graphene, it turns out, is no different from the glass fibers Griffith tested.

“Everybody thinks the carbon-carbon bond is the strongest bond in nature, so the material must be very good, ” Lou said. “But that’s not true anymore, once you have those defects. The larger the sheet, the higher the probability of defects. That’s well known in the ceramic community.”