Academic leads: Dr Sameer Rahatekar, Dr Bo Su

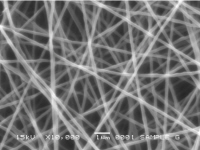

An electrospinning technique has been used to produce polymer, ceramic and nanocomposite nanofibres for wound addressing, tissue engineering and dental composites applications. The electrospun nanofibres have typical diameters of 100-500 nm. Natural biopolymers, such as alginate, chitosan, gelatin and collagen nanofibres, have been investigated. Novel nanocomposites, such as Ag nanoparticles doped alginate nanofibres and alginate/chitosan core-shell nanofibres, have also been investigated for antimicrobials and tissue engineering scaffolds. Zirconia and silica nanofibre/epoxy composites are currently under investigation for dental fillings and aesthetic orthodontic archwires.

Modelling and design of nanoinclusions

Modelling and design of nanoinclusions

We have developed a series of simulations tools consisting on hybrid atomistic-continuum models to simulate and predict the mechanical properties of a large class of nanostructures (carbon nanotubes, graphene, boron nitride sheets and tubes, zinc oxide nanowires). The models are implemented in commercial Finite Element codes, and allow to predict linear and nonlinear mechanical properties, as well as vibration and piezoelectricity of the nanostructures considered. We have been successful in identifying the shear modulus of CVD graphene from experimental tests, and discern the effect of the substrates from the intrinsic mechanical performance of the carbon layer. We use these models to predict the multiphysics properties of nanocomposites made with classic nanoinclusions, but also to design and tailor the geometry of other nanostructures (like carbon nanotube hetero-junctions), to help develop the next generation of NEMS and nanosensors.

Clay nanocomposites

Natural clays offer a wide variety of particle shapes and sizes, and high aspect ratios are achievable with montmorillonite sheets of 1 nm thickness, and sepiolite rods of 25 nm diameter. However, in order to realise composite materials in which highly non-spherical shapes are exploited, a good degree of dispersion of the particles is essential. This is achieved using a variety of surface treatments that make clay minerals compatible with solvents, polymers or liquid crystals. It is found that well-dispersed particles spontaneously form aligned (nematic) structures on increase of concentration. Potential applications include hierarchical polymer composites and novel liquid crystal displays.