Embedding sensors and electronics inside of 3D objects in a single build process has been a long sought after goal in 3D printing (3DP). A group led by Simon Leigh, at the University of Warwick in England, has now done just that. Leigh’s group developed a low-cost material they call carbomorph – a carbon black filler in a matrix of a biodegradable polyester.

In addition to being conductive, carbomorph is piezoresistive. This means which that when it is bent or stressed, its resistance changes. Typically the resistance increases as the object is bent because the conductive grains are spread further apart. Piezoresistive strips of carbon nanotubes have been created previously by other groups and used in the measurement of movement, but printing them is something new.

The goal of Leigh’s group was to completely print a motion sensing glove in a single unbroken run. This required a machine with multiple heads, and their Bits from Bytes BFB3000 fit the bill. In one head they used used polylactic acid (PLA) to print the main body of the glove. The other head contained the carbomorph for the embedded sensing strips in each finger. The cross section of embedded strip was only .25 square microns yet proved sufficient for getting a robust piezoelectric signal to compute the bend angle.

The goal of Leigh’s group was to completely print a motion sensing glove in a single unbroken run. This required a machine with multiple heads, and their Bits from Bytes BFB3000 fit the bill. In one head they used used polylactic acid (PLA) to print the main body of the glove. The other head contained the carbomorph for the embedded sensing strips in each finger. The cross section of embedded strip was only .25 square microns yet proved sufficient for getting a robust piezoelectric signal to compute the bend angle.

In an effort to make their work freely available they published it in the open access journal PLoS ONE. The piezoresistive measurements were done using the popular Arduino Uno interface board and captured with Processing, an open-source software package for visualizing and manipulating data.

The group also printed capacitive buttons of the kind used in many common touch sensors, or as mouse replacements for human interface devices (HIDs). Capacitive measurements were also carried out with an Arduino, and implemented with the CapSense code library. The ability to print capacitive sensors potentially opens up 3DP to new areas including accurate measurement of distance, humidity, or acceleration.

The group also printed capacitive buttons of the kind used in many common touch sensors, or as mouse replacements for human interface devices (HIDs). Capacitive measurements were also carried out with an Arduino, and implemented with the CapSense code library. The ability to print capacitive sensors potentially opens up 3DP to new areas including accurate measurement of distance, humidity, or acceleration.

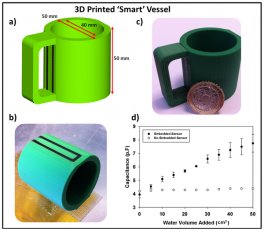

For the group’s final demonstration, things start to really get interesting. Two vertical capacitive sensor strips were embedded in the wall of a 3DP mug. This “smart vessel” yielded a reliable capacitance measurement which scaled linearly with the height of the fluid in the cup. One might imagine inexpensive party cups which report and summon a refill whenever a guest’s drink falls below a certain level.

Conductive 3D-printed materials, by nature of their composition, have only a fraction of metal or carbon’s electrical conductivity. Therefore at any interface with other electronics, where there will already be some unavoidable loss of any signal, extra care must be taken. It is for this reason that high-end audiophiles are willing to spend the extra money for gold-plated contacts — more signal is transduced and less is absorbed or reflected back to induce ringing or other unwanted noise.