Using a new a printing process called FLUENCE (fluid-enhanced crystal engineering), researchers have developed highly aligned single-crystalline organic semiconductor thin films that are capable of conducting electricity 10 times more efficiently than those created using conventional methods.

Using a new a printing process called FLUENCE (fluid-enhanced crystal engineering), researchers have developed highly aligned single-crystalline organic semiconductor thin films that are capable of conducting electricity 10 times more efficiently than those created using conventional methods.

Menlo Park, California — Through innovations to a printing process, researchers have made major improvements to organic electronics—a technology in demand for lightweight, low-cost solar cells, flexible electronic displays and tiny sensors. The printing method is fast and works with a variety of organic materials to produce semiconductors of strikingly higher quality than what has so far been achieved with similar methods.

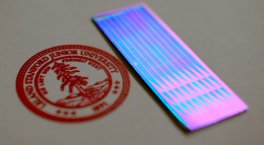

Organic electronics have great promise for a variety of applications, but even the highest quality films available today fall short in how well they conduct electrical current. The team from the U.S. partment of Energy’s (DOE) SLAC National Accelerator Laboratory and Stanford University have developed a printing process they call FLUENCE—fluid-enhanced crystal engineering—that for some materials results in thin films capable of conducting electricity 10 times more efficiently than those created using conventional methods.

partment of Energy’s (DOE) SLAC National Accelerator Laboratory and Stanford University have developed a printing process they call FLUENCE—fluid-enhanced crystal engineering—that for some materials results in thin films capable of conducting electricity 10 times more efficiently than those created using conventional methods.

“Even better, most of the concepts behind FLUENCE can scale up to meet industry requirements, ” said Ying Diao, a SLAC/Stanford postdoctoral researcher and lead author of the study, which appeared today in Nature Materials.

Stefan Mannsfeld, a SLAC materials physicist and one of the principal investigators of the experiment, said the key was to focus on the physics of the printing process rather than the chemical makeup of the semiconductor. Diao engineered the process to produce strips of big, neatly aligned crystals that electrical charge can flow through easily, while preserving the benefits of the “strained lattice” structure and “solution shearing” printing technique previously developed in the lab of Mannsfeld’s co-principal investigator, Professor Zhenan Bao of the Stanford Institute for Materials and Energy Sciences, a joint SLAC-Stanford institute.