A variety of functional thin films can be produced using the layer-by-layer (LbL) assembly technique. Thin films, typically < 1µm thick, are created by alternately exposing a substrate to positively- and negatively-charged molecules or particles.

A variety of functional thin films can be produced using the layer-by-layer (LbL) assembly technique. Thin films, typically < 1µm thick, are created by alternately exposing a substrate to positively- and negatively-charged molecules or particles.

The movie below illustrates the layer-by-layer assembly process using a polycation (positively-charged polymer) and anionic clay platelets, which is the basis for our gas barrier and anti-flammable technologies. Each individual layer may be 1 – 100+ nm thick depending on: chemistry, molecular weight, charge density, temperature, deposition time, counter ion, and pH of the species being deposited.

The ability to control coating thickness down to the nm-level, easily insert variable thin layers without altering the process, economically use raw materials (due to thin nature), self-heal, and process under ambient conditions are some of the key advantages this deposition technique has.

The PNC Lab is currently studying LbL-based thin films as a super gas barrier (i.e. foil replacement material), an anti-flammable coating for foam and fabric, antimicrobial surfaces, electrochromic thin films and electrically conductive layers that can be patterned using traditional photolithography.

Super Gas Barrier

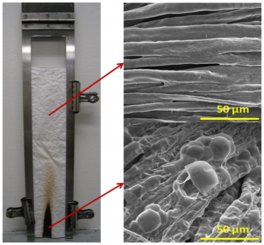

The processing of clay-based composites is a challenge, and it is nearly impossible to incorporate more than a few weight percent (without causing significant aggregation) in bulk composites. Depositing clay in a layer-by-layer fashion creates thin films that are fully dense, completely transparent, and contain as much as 80 wt. % of completely exfoliated clay (ACS Applied Materials & Interfaces 2010).

The processing of clay-based composites is a challenge, and it is nearly impossible to incorporate more than a few weight percent (without causing significant aggregation) in bulk composites. Depositing clay in a layer-by-layer fashion creates thin films that are fully dense, completely transparent, and contain as much as 80 wt. % of completely exfoliated clay (ACS Applied Materials & Interfaces 2010).

These “nano brick wall” films (see figure below) act as impressive gas barriers, with many film structures yielding an oxygen transmission rate (OTR) below 0.005 cm3/m2 day (0%RH, 23oC). Even with short (5 second) dip times, films created with 30-bilayers of polyethylenimine (PEI) and natural montmorillonite (MMT) clay have been shown to maintain these super barrier properties (Industrial & Engineering Chemistry Research 2010).

gold xbox 360 controller gold x auto sales gold x ring gold xlr gold yellow gold yarn gold ysl heels gold youtube play button gold ysl bag gold yachtmaster gold yahoo finance gold yacht gold zippo gold zeo ranger gold zebra loach gold zekrom gold zacian v gold zamazenta gold zelda nes gold zodiac necklace gold about to explode gold about information gold about to crash gold about 2019 gold about sentence gold about history gold about rate gold after hours gold after 5 dress gold after etf gold after five shoes gold after 50 gold after america tour gold after five dresses gold after hours price gold against the soul gold against inflation gold against us dollar gold against inflation chart gold against loan gold against dollar gold against cash gold against the soul vinyl gold among us gold among us character gold among us pop it gold among the dross gold among the sand gold among us wallpaper gold among the dross meaning gold among us logo gold around america tour gold around pupil gold around the world gold around tooth gold around me gold around teeth gold around the american flag gold around iris gold as an investment gold as inflation hedge gold as a gas gold as a hedge against inflation gold as a conductor gold as an element gold as currency gold as an investment 2021 gold at the bottom of the ocean gold at the bottom of lake michigan gold at the bottom of the pyramid gold at the bottom of niagara falls goldfish at bottom of tank gold at bottom of world trade center gold at bottom of waterfall gold at bottom of american flag gold at the top of the pyramids gold brick top of moving stairs top golf what happened to the gold at the top of the pyramids what happened to the gold on top of the great pyramid gold at the end of the rainbow gold at room temperature gold at fort knox gold at spot gold at the end of the rainbow meaning gold at walmart gold at world trade center gold at higher levels 5e gold before and after etf gold before it is refined gold before processing gold before purification gold before election gold before you wake up gold before mining before gold coast what was the name of ghana gold behind the couch table gold behind currency gold behind waterfall rdr2 gold behind boulders gold behind glass