University of Chicago, University of Illinois rightOriginal Study

University of Chicago, University of Illinois rightOriginal Study

The ability to fabricate nanostructures out of polymers, DNA, proteins, and other “soft” materials has the potential to enable new classes of electronics, diagnostic devices, and chemical sensors.

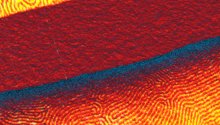

This atomic force microscope image shows two different printed lines of block copolymers, colored and scaled by the microscope’s software. Each block copolymer has a different molecular weight and therefore has a different size and spacing of its structural components. The repeating structures at left have a spacing of 41 nanometers, while those at right have spacing of 27 nanometers. (Credit: Serdar Onses/U. Illinois at Urbana-Champaign)The challenge is that many of these materials are fundamentally incompatible with the sorts of lithographic techniques that are traditionally used in the integrated circuit industry.

Recently developed ultra high-resolution ink jet printing techniques have some potential, with demonstrated resolution down to 100-200 nanometers, but there are significant challenges in achieving true nanoscale dimension.

“Our work demonstrates that processes of polymer self-assembly can provide a way around this limitation, ” says John Rogers, professor of materials science and engineering at University of Illinois at Urbana-Champaign.

Combining jet printing with self-assembling block copolymers enabled the engineers to attain the much higher resolution, as suggested by lead author Serdar Onses, a postdoctoral scientist at Illinois. Onses earned his doctorate at the University of Wisconsin under Paul Nealey, now professor of molecular engineering at the University of Chicago and a co-author of the paper in .

Combining jet printing with self-assembling block copolymers enabled the engineers to attain the much higher resolution, as suggested by lead author Serdar Onses, a postdoctoral scientist at Illinois. Onses earned his doctorate at the University of Wisconsin under Paul Nealey, now professor of molecular engineering at the University of Chicago and a co-author of the paper in .

“This concept turned out to be really useful, ” Rogers says.

Engineers use self-assembling materials to augment traditional photolithographic processes that generate patterns for many technological applications. They first create either a topographical or chemical pattern using traditional processes. For the new paper, this was done at imec in Belgium, an independent nanoelectronics research center.

Nearing the limits

The resolution of the chemical pattern nears the current limit of traditional photolithography, notes Lance Williamson, a graduate student in molecular engineering at University of Chicago and co-author of the article. “Imec has the capability to perform the photolithography at this scale over large areas with high precision, ” Williamson says.

Back at the University of Illinois, engineers place a block copolymer atop this pattern. The block copolymer self-organizes, directed by the underlying template to form patterns that are at much higher resolution than the template itself.